Radio Remote Controlled Drill Rig

Furukawa DRC 20 drill rig full remote-controlled operation.

Riko Control Systems, together with their strategic partners, completed the upgrade of a Furukawa drill rig to full radio remote control for a client.

The system allows the operator to control the machine with an industrial radio remote control from outside the cab. The remote control system enables full machine control remotely, allowing all functions that are available in the cab to be accessed from the remote control.

The drilling rig can perform various operations ranging from production blast-hole drilling, pre-split high-wall support, opencast mining roadway maintenance and rehab, drilling of drainage holes, rockfall mitigation and anchor hole drilling.

The retrofit allows for the following benefits to be realised:

Safety improvements.

The drill rig mostly works in hazardous conditions where operator safety can be an issue. By removing the operator from the cab and remotely controlling the machine, safety issues are no longer a concern.

Increased machine utilisation.

Where safety concerns limited the machine utilisation in the past, it is no longer a factor and the machine can now be applied more productively.

Control systems redundancy.

The remote control system allows for redundancy and downtime decreases. When control from the cab is faulty or irregular, the radio remote control system gives the operator a backup control system to perform all the functions as are available in the cab.

Increase of overall view of surrounding areas.

The cab limits the overall view of the surrounding work area. By controlling the drill rig from outside, the operator can identify pain points quickly and accurately.

Logging of drilling data and operator performance.

By logging drilling data, operator performance and drill rig performance can be monitored to identify productivity and performance problems thus improvement opportunities can be realised. Log files can be downloaded via USB and Wi-Fi.

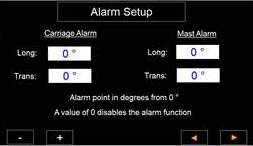

Automated drilling alignment.

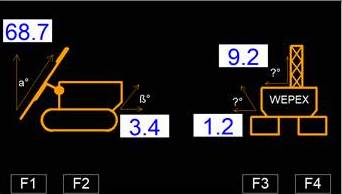

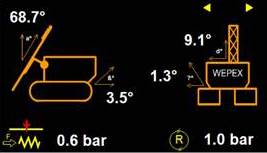

Hole drilling data can be uploaded via USB to the control interface. This enables the drilling rig operator to see comprehensive drilling diagrams for ring hole drilling. The dual inclination system allows for accurate measurement, display and logging of hole depth, swing- and dip angles.

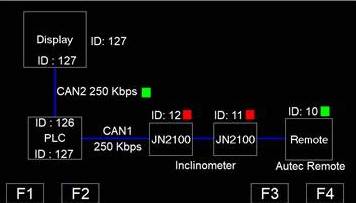

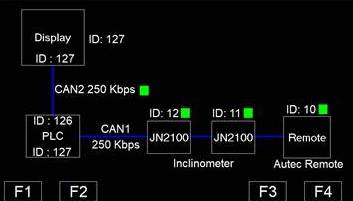

The remote integration features applied includes:

- Custom remote software and firmware programming.

- Hydraulic interface with hydraulic valves.

- Drilling inclination system for horizontal and vertical drilling angles.

- Machine chassis inclination system to prevent tipping with operator warning signals.

- Drill boom angle indication system.

- Machine vital monitoring.

- Drill feed and rotation pressures.

- Hydraulic and air pressure display.