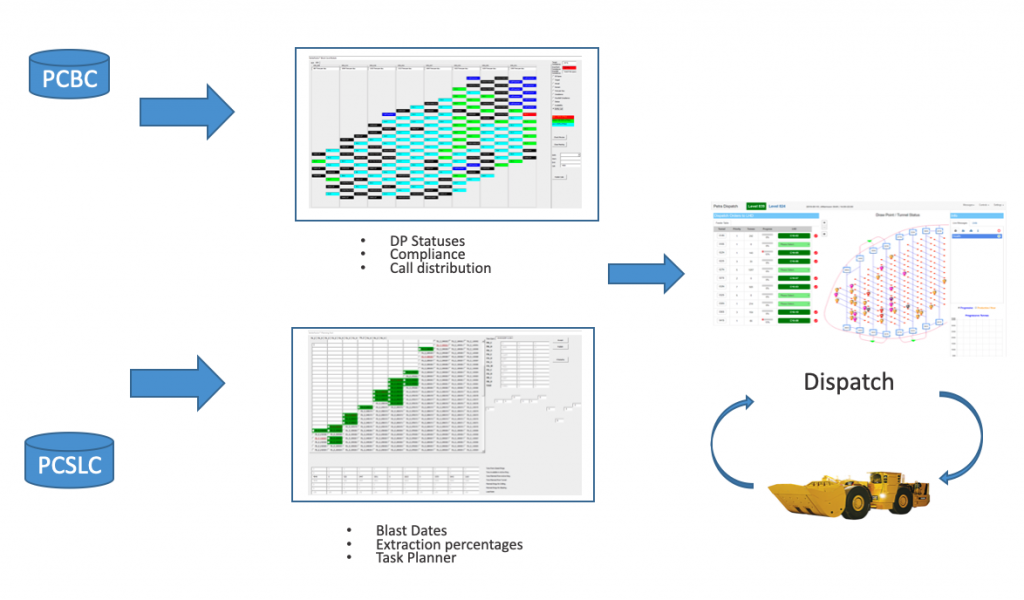

Mining Draw Control System

Underground mining production planning, assignment and monitoring

The Riko Control Systems underground mining draw control system is a comprehensive system developed in-house to cater for the underground mining sector.

This comprehensive system was developed to custom specifications as required by the client and is a ongoing project as the client regularly request added functionality and integration.

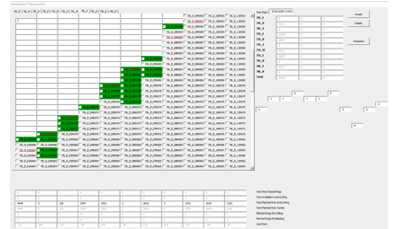

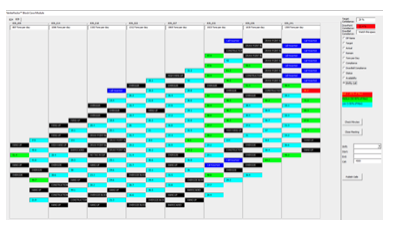

Draw Control Information Flow:

- Production planning for drilling, blasting and loading is published to SQL.

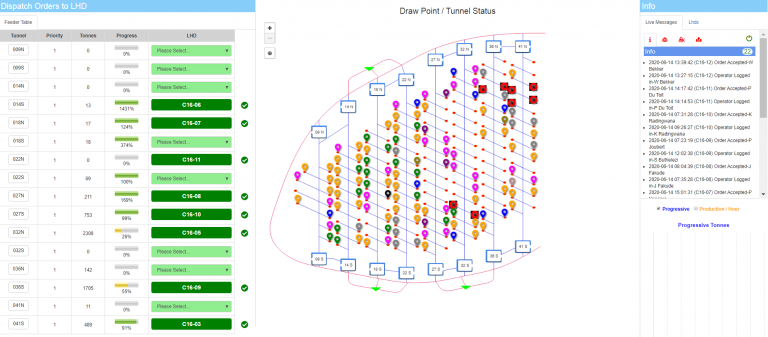

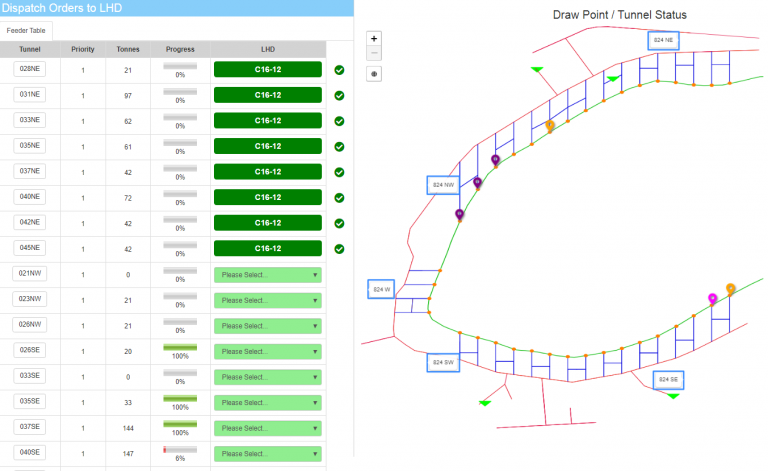

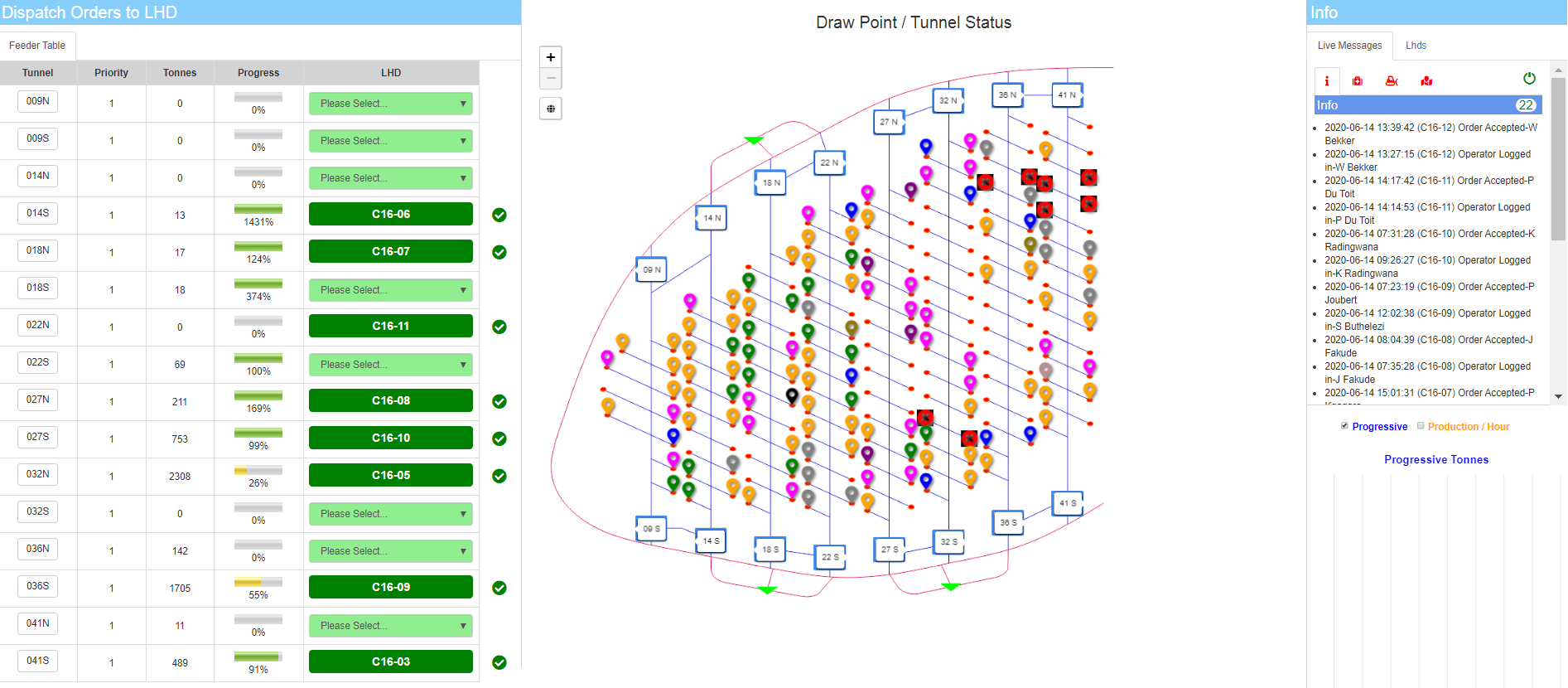

- The planning data is imported into an HTML based user interface (UI).

- Production staff use the UI to assign production areas to specific machines and operators.

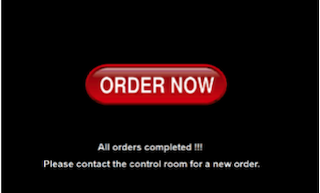

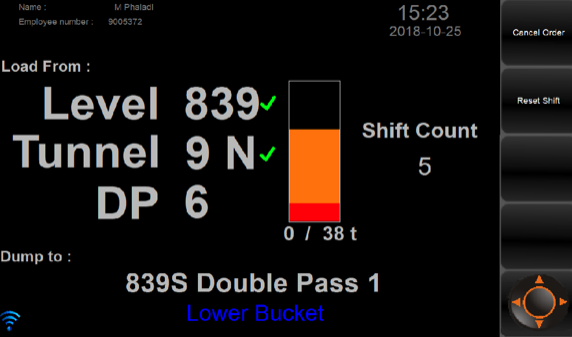

- Production orders are converted to .CSV and sent to the machine operator display.

- Production progress is tracked in real time.

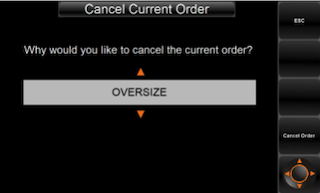

- Production delays and blocked areas is logged on the operator display and fed back to the UI to reflect the area status.

- New production orders are requested by operators whereby the UI will alert production staff of request.

- Break-downs are logged by operators and displayed on the UI.

- Two way message communication between operator and controller displayed on the UI.

- Core production, health and general info sent from machines to be displayed in UI.

- Automatically send draw orders of previously blocked areas when affected area has been restored to production status.