Hardware Solutions

Unlocking Machine Data

To support our Software systems we have developed core hardware components that unlock the data potential of under-ground assets:

- BRICK: data logging and control for TMM’s

- Smart Antenna: Real-time positioning for under-ground TMM’s

- TMM Load tracking system: Our TMM interface for under-grounnd TMM load tracking and Dispatch & Rostering

- Custom under-ground Wi-Fi systems for rapid deployment

Typical hardware systems integration includes:

- Boom & Bucket Pressure Sensors

Determines when actual loading takes place or production processes take place

- RFID Readers

Reading of tags placed in strategic tunnel positions for production data capturing and asset tracking

- Operator Display

Operator authentication

Work orders

Display production data

Fault finding interface

- Data Loggers

Calculates and buffers production cycles

Provides gateway for real-time data

Auxiliary control

Integrated into operator display

- WLAN Radio

Communications link to the surface – reliable and fast

Project examples

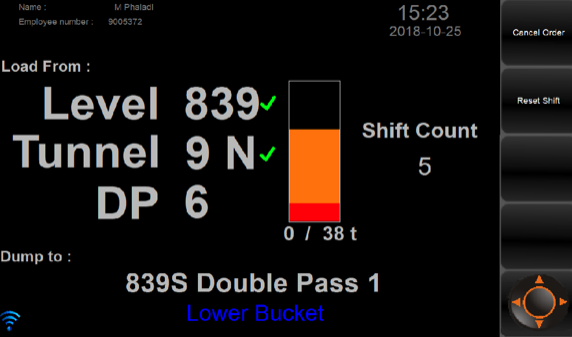

LHD or Truck operator display

Features included:

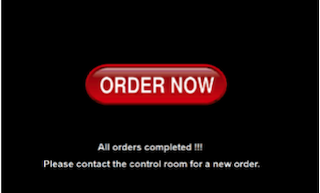

- Orders are received in real-time from Dispatch UIBased on default bucket capacity

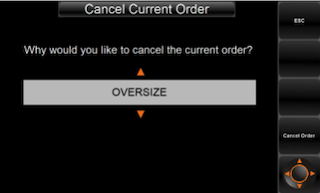

- Orders can only be completed by reaching call or by cancelling an order with a reason (oversize, misfires etc.)

- Cancel reasons displayed in real-time on surface dispatch UI (dependant on Wi-Fi Coverage)

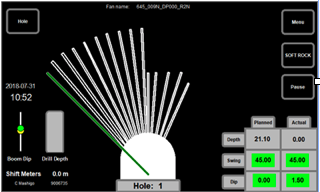

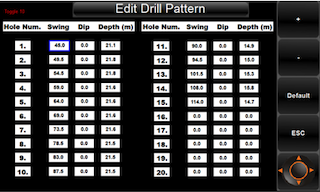

Underground Drill Rig Operator Display

Features included:

- Automatic Drill boom alignment for angle, dip and swing.

- Drill depth detection

- Auto drill hole parameters

- Rock type selection

- Access to technical maintenance options

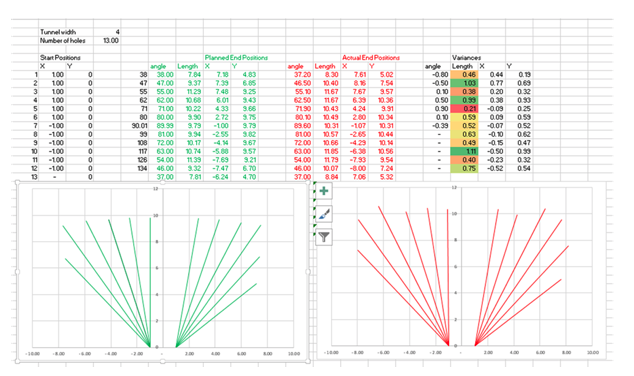

- Data logged to .csv format

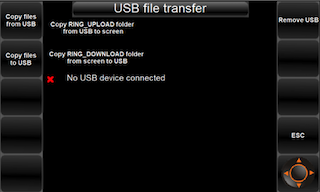

- Log files downloaded via Wi-Fi